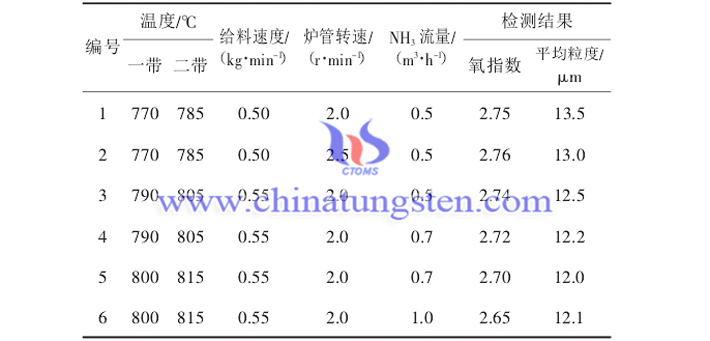

Nano violet tungsten oxide for producing thermal insulation paper can be prepared by hydrogen reduction in an industrial rotary furnace under the conditions of wet hydrogen and high temperature with APT as raw material. Then, the four main process parameters affecting the performance of violet tungsten were selected as the research object, furnace temperature, furnace tube speed, feed rate and NH3 flow rate, to carry out the optimization experiment. And the experimental results are as follows:

It can be seen from the data in the above table that the furnace temperature, furnace tube speed and feed rate have a great influence on the performance of violet tungsten oxide. The NH3 flow rate and exhaust system also have an effect on the performance and production of the violet tungsten oxide.

In other words, with other conditions unchanged, if the temperature is too high, the feed rate is too low, and the furnace tube speed is too slow, the material will be excessively reduced, resulting in an increase in the phase content of WO2 or the appearance of W phase. On the contrary, APT cannot be completely converted into W18O49 phase, resulting in an increase in W20O58, ATB and other phases. Therefore, the changes of these three parameters directly determine the phase composition of the violet tungsten oxide powder.

More details, please visit:

http://www.tungsten-powder.com/violet-tungsten-oxide.html