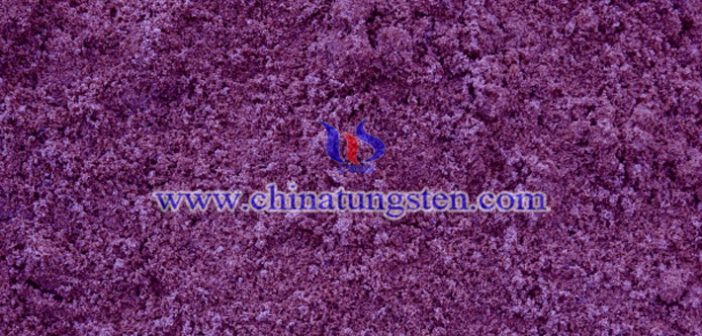

Violet tungsten oxide powder for manufacturing infrared thermal insulation nano material can be prepared by APT wet hydrogen direct reduction method. The specific processes are: A certain amount of APT is loaded into the boat and pushed into the high temperature zone of the reduction furnace. At the same time, a certain proportion of H2 and steam mixed gas is fed, heated to the specified temperature and cooled for a suitable time, then cooled, cooled to room temperature, and heated, kept warm, cooled. The gas flow rate does not change during the process.

Studies have shown that when using this method to prepare violet tungsten oxide, the higher the humidity of hydrogen is, the higher the temperature required to obtain violet tungsten oxide is. When the humidity of hydrogen is too small, the temperature range of the obtained violet tungsten oxide is narrow, which is difficult to control in production. Therefore, pH2O:pH2 is set to about 1.7:1. According to the relationship between the equilibrium constant of the reduction reaction and the temperature, the maximum temperature of the obtained violet tungsten oxide is 1338K, and the lowest temperature is 924K.

More details, please visit:

http://www.tungsten-powder.com/violet-tungsten-oxide.html