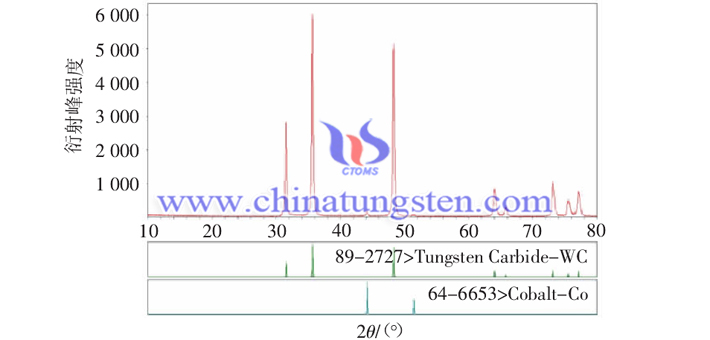

Nanometer violet tungsten oxide may be applied for the manufacture of thermal insulation dispersion liquid, which may be used for the production of thermal insulation films, and then be applied in the fields of construction and automotive. Violet tungsten oxide can also act as a raw material in the preparation of nano grain size WC-Co composite powder by spray drying-direct carbonization. Some scholars have studied the X-ray diffraction pattern of WC-Co composite powder prepared by hydrogen reduction at 950°C and found that:

The obtained composite powder has a pure phase with no η phase. And the crystal grains are fine. Generally, the carbonization temperature of WC is about 1300°C or higher. However, the hollow spherical shell structure of precursor composite powder has a large amount of pores and a high specific surface area. The specific surface area of the powder is large and the surface energy is high, so that the flow and diffusion between the powders of H2 is easier, which is beneficial to lower the reduction carbonization temperature and increase the reaction rate. And the CH4 generated by the reaction of C and H2 is preferentially decomposed and precipitated on the surface of Co particles. And therefore C is easier to diffuse into the contact area with W with high activity. Therefore, the composite powder can be completely carbonized at a low temperature of 950°C.

More details, please visit:

http://www.tungsten-powder.com/violet-tungsten-oxide.html