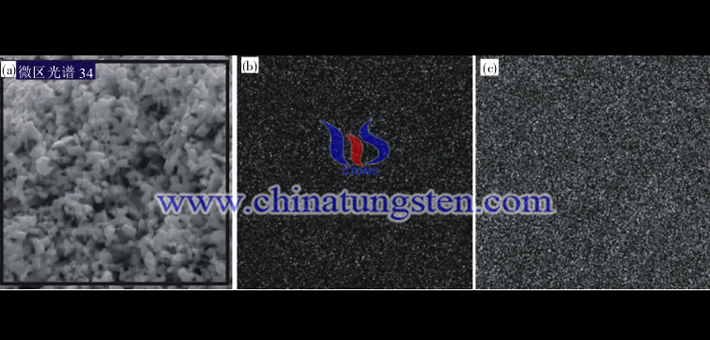

Nanometer violet tungsten oxide may be applied for producing thermal insulation dispersion, and therefore be applied to prepare thermal insulation films that require high thermal insulation and high visible light transmittance. Violet tungsten oxide can also be used in spray drying-direct carbonization to prepare nano particle size WC-Co composite powder. Some scholars have observed the SEM surface distribution image of WC-Co prepared at 950°C and found that:

In the image, (a) is an enlarged SEM photograph of the 20,000-fold powder; (b) is a surface distribution diagram of the Co element after amplification, and (c) is a surface distribution diagram of the W element after amplification. The black highlight in the photo is cobalt. The more black highlights in the image are, the greater the density of Co in this region is. And the phase distribution of cobalt is more uniform. The gray highlight in (c) is the W element distribution. It can be seen from (b) and (c) that the Co and W elements are densely distributed on the spherical particles, and the Co phase uniformly coats and bonds with the WC grains. That is to say, the Co phase of the nano WC-Co composite powder prepared by the process is uniformly coated around the WC grains without components segregation.

More details, please visit:

http://www.tungsten-powder.com/violet-tungsten-oxide.html