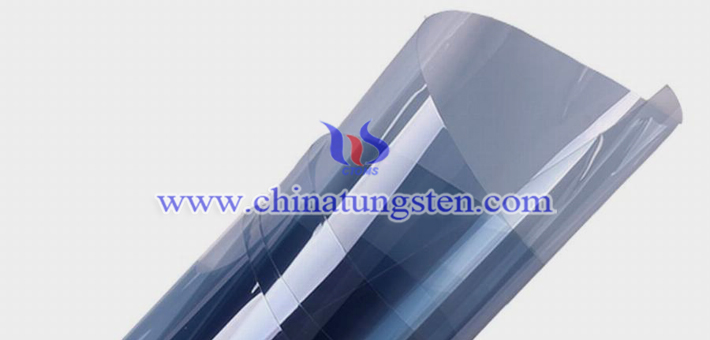

Dark blue nano tungsten oxide may be applied for preparing transparent thermal insulation material. Certainly, the application of blue tungsten oxide is not limited to this. Blue tungsten oxide can also be used for the preparation of tungsten powder by cyclic redox process. Some scholars have studied the effect of cyclic redox of blue tungsten oxide on the particle size distribution of tungsten powder. They found that:

1.0 First reduction. Blue tungsten oxide is first reduced to tungsten powder in hydrogen. The first reduction of the blue tungsten oxide to the tungsten powder has a smaller particle size, but there is a certain amount of coarse particle size tungsten powder. The specific surface area of the tungsten powder was 0.119m2/g, which was 1.95 times of the specific surface area of the blue tungsten oxide. It is known that the particle size of the tungsten powder after the first reduction is smaller than the particle size of the blue tungsten oxide. The particle size is 89.23% between 5μm and 15μm, and 6.34% between 2μm and 5μm, and 4.03% between 15μm and 21μm. Compared with the particle size distribution of blue tungsten oxide, the particle size of the tungsten powder after the first reduction becomes fine, and the coarse particles are quantitatively reduced, and the particle size distribution is relatively concentrated.

2.0 Second reduction. The first reduced tungsten powder is oxidized to tungsten trioxide in air and the tungsten powder is reduced a second time in hydrogen. The particle size of the second reduction to tungsten powder is also significantly smaller, the proportion of fine grain size tungsten powder is increased, and its particle size distribution is relatively uniform, however, there is a small amount of coarse grain size tungsten powder.

More details, please visit:

http://www.tungsten-powder.com/Blue-Tungsten-Oxide.html