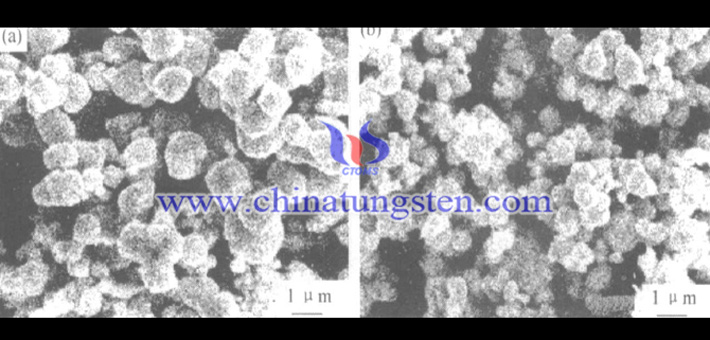

Blue tungsten oxide powder for thermal insulation thin film can be used as a raw material for the preparation of tungsten powder. Under the premise of blue tungsten oxide of stable quality, the reduction process conditions play a decisive role in the particle size of tungsten powder. In the process of preparing fine tungsten powder using blue tungsten oxide as a raw material by hydrogen reduction, factors such as reduction temperature, heating rate, hydrogen flow rate, hydrogen humidity, material layer thickness, pushing speed, and loading capacity must be strictly controlled, as the particle size of tungsten powder changes accordingly as the process conditions change. The SEM image of W powder produced with activated blue tungsten oxide powder is as shown as below.

It can be seen from the experimental results that as long as the process conditions of the reduction process are properly controlled, ultrafine tungsten powder can be prepared, and the particle size distribution of the prepared tungsten powder is relatively uniform.

More details, please visit:

http://www.tungsten-powder.com/Blue-Tungsten-Oxide.html