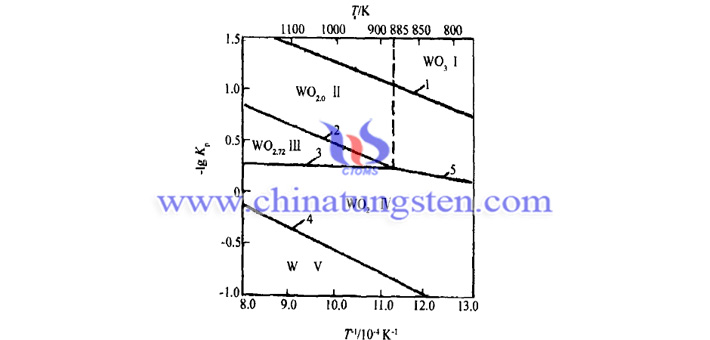

Nano grain size blue tungsten oxide for thermal insulation thin film can be used to prepare tungsten powder of fine particle size. However, in the process of directly preparing fine tungsten powder by hydrogen reduction of blue tungsten oxide, the reduction conditions should be strictly controlled to avoid the generation of violet tungsten (WO2.72). This conclusion can be drawn from the thermodynamic analysis of hydrogen reduction of blue tungsten oxide. Image of ΔG° T in hydrogen reduction of tungsten oxides is shown as below.

Through chemical equilibrium studies, it was found that the hydrogen reduction generally undergoes the following changes: WO2.9→WO2.72→WO2→W. However, practice shows that the reaction mechanism of the process is very complicated due to the control conditions, which is mainly affected by factors such as reduction temperature and hydrogen humidity.

If the reduction temperature is around 600°C, the main phase composition of blue tungsten oxide during reduction process in dry hydrogen is changed from WO2.9 to W, that is, the reaction is mainly carried out in a direct manner from WO2.9 to α-W and β-W, and fine tungsten powder is obtained. If the temperature is higher than 800°C, the main phase composition of blue tungsten oxide during the hydrogen reduction process is changed: WO2.9→WO2.72→WO2→W, which will produce WO2.72 and WO2 crystals, resulting the tungsten powder obtained is thicker. Therefore, it is necessary to strictly control the reduction process conditions to avoid the generation of WO2.72.

More details, please visit:

http://www.tungsten-powder.com/Blue-Tungsten-Oxide.html