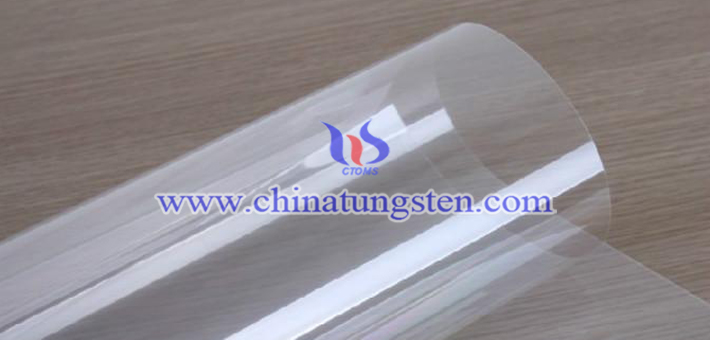

Transparent thermal insulation film may be prepared by using blue tungsten oxide powder as raw material. And therefore, such material can be used in window glass of building and automobile where requiring high transparency and high ultrviolet shielding rate.

While as you may have known blue tungsten oxide can be used in a rotary kiln in hydrogen reduction process to produce tungsten powder. The raw material required for the process is blue tungsten oxide, the FSSS particle size is (11-14)μm, the bulk density is (2.2-2.5)g/cm3, and the chemical composition meets the technical requirements of the product. The equipment required includes an industrial rotary reduction furnace and a four-tube reduction furnace.

Industrial rotary reduction furnace: The maximum working temperature is 1050°C, the furnace tube diameter is 450mm, the heating belt length is 4500mm, the inclination angle is 0°~3°, the rotation speed is (0.9~3.3)r/min, and the total length of the furnace tube is 8000mm. Four-tube reduction furnace: furnace tube size of 300mm×270mm×6000mm, the maximum working temperature is 950°C.

After that, the resulting data needs to be processed. Data processing method: tungsten powder prepared by different process parameters and the corresponding tungsten carbide powder were respectively measured for the supply state and the average particle size of the ground state. The average of 5 consecutive batches was taken as the tungsten powder particle size value under the process conditions.

More details, please visit:

http://www.tungsten-powder.com/Blue-Tungsten-Oxide.html