Tungsten oxide - nickel oxide composite electrochromic film can be prepared by a screen printing method. For example, some experts have prepared a Mo doped WO3 electrochromic thin film by screen printing, and found that:

More details, please visit:

http://www.tungsten-powder.com/tungsten-oxide.html

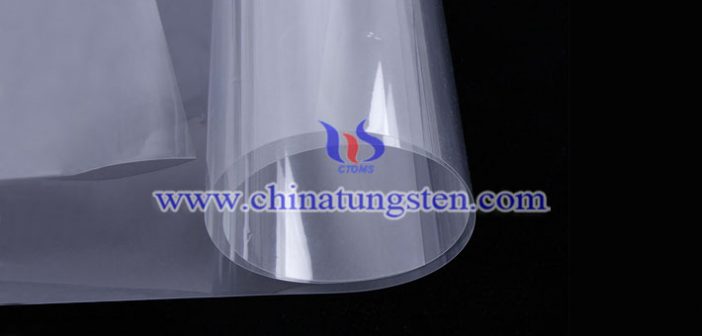

After the heat treatment at 500 °C, the transmittance of the tungsten trioxide electrochromic thin film obtained at one printing was as high as 78%. Moreover, the WO3 electrochromic film has a high light modulation range after heat treatment. But why? This is because the WO3 film after heat treatment has a denser structure, which facilitates the injection and extraction of lithium ions. This also means that the heat-treated tungsten trioxide composite electrochromic film has more excellent electrochromic properties. That is to say, the obtained electrochromic thin film will have higher near infrared shielding rate, ultraviolet shielding rate and visible light transmittance, so such heat insulating film is more and more popular in building.