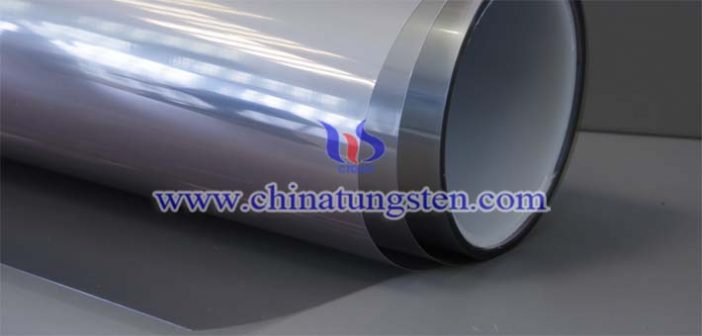

Cs0.32WO3 is mainly applied for preparing heat insulation film. And such a dingal film is more and more widely applied to buildings and automobiles. Wherein, the light absorption performance of Cs0.32WO3 is greatly affected by its grain size, morphology, and crystallinity. That is to say, the near-infrared shielding performance of a transparent thermal insulation film using Cs0.32WO3 nano powder as a dingal material is significantly affected by the grain size, morphology, and crystallinity of Cs0.32WO3 powder.

More details, please visit:

http://cesium-tungsten-bronze.com/index.html

It is reported that some experts have used nano SiC as a calibration standard to correct the crystallinity of Cs0.32WO3 for thermal insulation film to better compare the crystallinity. But why choose SiC as a calibration substance? The reason for choosing SiC as a calibration substance is that SiC has few diffraction peaks (SiC Standard Card (JSPDFNO.29-1129)), and its diffraction peaks do not coincide with the Cs0.32WO3 diffraction peak.