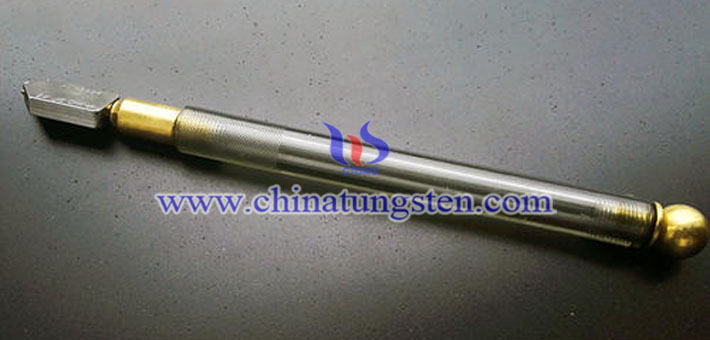

New tungsten carbide glass cutter adopts a tungsten carbide substrate as the cutter body. And it is coated with a diamond-like coting of thickness of 1-10 microns. The diamond-like coating on new tungsten carbide glass cutter can improve the hardness and wear resistance of the cutting edge. When cutting hard glass, the coating film can significantly increase the life of the glass cutter.

More details, please visit:

http://www.tungsten-carbide.com.cn/tungsten-carbide-blade-bar.html

So, why choose a diamond-like coating instead of a diamond coating? The reason is that the deposition temperature of the diamond-like film is relatively low. It can be deposited at room temperature, so that the influence of Co in tungsten carbide materials on the film is not great, and the hardness of the tool can also be improved.

What is a diamond-like coating? The diamond-like coating is a metastable amorphous carbon composed of sp2 hybridized carbon and sp3 hybridized carbon. It has high hardness, high optical transmittance, good mechanical and frictional properties, therefore it has good application prospects in the fields of machinery, electronics, optics and so on.