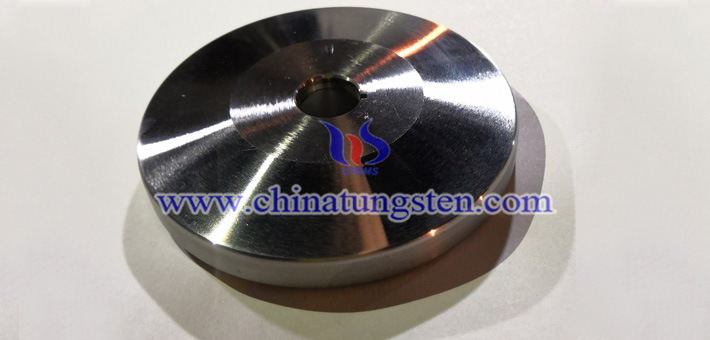

Tungsten alloy X-ray anode target is widely used in medicine and materials. Wherein, tungsten alloy has characteristics of good thermal conductivity and electrical conductivity, high temperature strength and wear resistance; target is an important component that generates X-rays.

More details, please visit:

http://www.tungsten-alloy.com/tungsten-alloy-radiation-shielding.html

You know, the quality of product affects its applications. According to the experts, there is white spot defects on the working surface of the X-ray anode target, which seriously affects the yield of product. So, they use optical microscope, scanning electron microscope and micro hardness analysis methods to analyze their microscopic composition. The results show that the white spot defect is a pit phenomenon in the microscopic view, and the surrounding grains are coarse. Experts analyzed the main reason for the defect is that the density and hardness of the material layer are different, sintering and hot pressing make the grain thicker and larger, and the grain is shed during the machining process, which is manifested as a pit phenomenon. Finally, by improving the production process, the experts effectively avoided the white spot defects on the surface of the target and improved the yield rate.