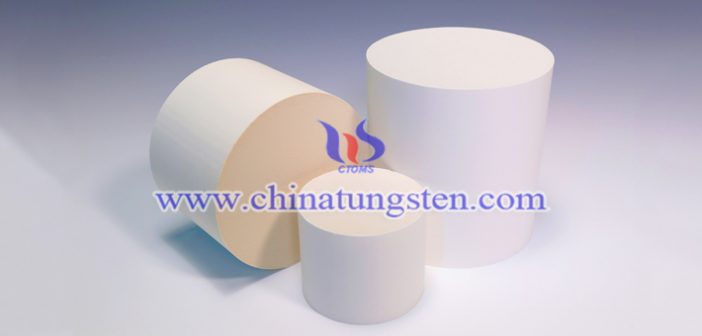

Ammonium metatungstate can be used to prepare high specific surface area porous ceramic catalyst, together with ammonium metavanadate, cerium nitrate and palladium acetate, as active components. The researchers proposed a method for preparing a porous honeycomb ceramic catalyst with high specific surface area, by mixing, aging, kneading, forming, drying and calcining.

More details, please visit:

http://www.ammonium-metatungstate.com/index.html

A Preparation Method of Porous Ceramic Catalyst

Step One: Prepare active ingredients. Add 60kg of water and 12kg of monoethanolamine to the dissolution tank respectively. When the temperature is controlled at 95 °C, add 12kg of ammonium metavanadate and 30kg of ammonium metatungstate to the dissolution tank, stir evenly, and add 15kg of citric acid to the dissolution tank and stir, add 7kg of cerium nitrate and 7kg of palladium acetate to the dissolution tank, to prepare the active component solution until they are all dissolved;

Step Two: Mixing, six times of mixing;

Step Three: The mixed raw materials are sealed and aged in an environment with a temperature of 20-30 °C and a humidity of 50-70%;

Step Four: After aging, the raw materials are filtered and fully kneaded, then aging again;

Step Five: The raw material extruder after the second aging is formed by the extruder, and then dried after packaging;

Step Six: Calcining the dried raw materials, the calcining temperature curve is parabolic, starting from room temperature, the maximum temperature is 615 °C, then the temperature gradually decrease, the kiln temperature is 80 °C, and the calcining time is controlled at 28h.