TIG welding cerium tungsten electrode usually contains small quantities of cerium oxide which can offer benefits as following as: facilitate arc starting, increase arc stability, improve current-carrying capacity of the rod, reduce the risk of weld contamination, and increase electrode life. Wherein, TIG welding is the short for tungsten inert gas welding, and is also known as gas tungsten arc welding (GTAW).

More details, please visit:

http://tungsten.com.cn/tungsten-needles.html

In a cerium tungsten electrode, cerium oxide is used as an alloying element to improve arc stability and ease of starting while decreasing burn-off. Cerium addition is not as effective as thorium but works well, and cerium is not radioactive. An alloy of lanthanum oxide has a similar effect as cerium, and is also not radioactive.

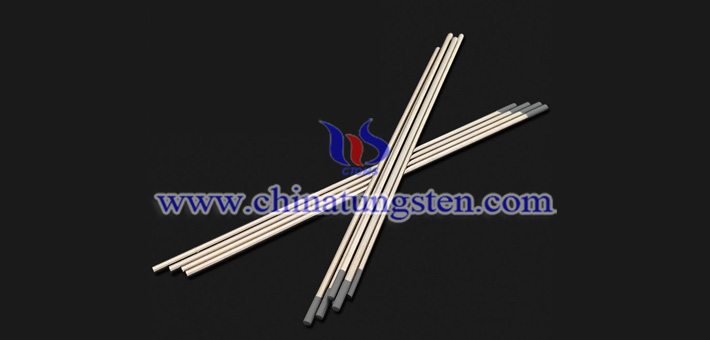

It is reported that cerium tungsten electrodes are used in TIG welding because they can withstand very high temperatures with minimal melting or erosion. TIG welding cerium tungsten electrodes are made by powder metallurgy and are formed to size after sintering.