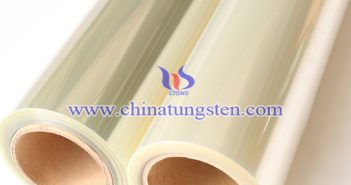

WO3 electrochromic film for heat insulating window glass has the highest coloring efficiency and excellent electrochromic properties, and thus it has been studied deeply, applied widely and developed extensively. For example, some experts have studied the relationship between the electrochromic coloring efficiency and the density of a tungsten trioxide film. More details, please visit: http://www.tungsten-powder.com/tungsten-oxide.html Experts pointed out that the coloring efficiency of electrochromic devices such as electrochromic window depends on the amount of charge inserted in the WO3 film.…