Tungsten components manufacture use Electron Beam Melting (abbreviation EBM) is an additive manufacturing method. Electrons accelerated under vacuum selectively melt metal powder andproduce a 3D component in an additive way layer by layer. The big advantage of this method consists in the energy source used the electron beam. It is used to pre-heat the metal powder and the carrier plate prior to melting, as a result of which deformation and inherent stress are reduced. It is possible to process materials…

Tungsten News

The ratio?of coated cemented carbide tools in metal processing industry is increasing steadily. In recent 10 years, its quality and?performance?have been significantly improved. On the one hand, due to the quality?improvement of the coating , it?will be better to control porosity and thickness; on the other hand, the metallurgical technology between the coating and the substrate interface has also been improved, therefore can?increase?the adhesion of the coating and prevent?the interfacial reaction that reduces the strength. Increasing cutting speed can significantly…

Pure tungsten bar is made of 99.95% tungsten?power and its forging and annealing process?is shown by test. The bar?has physical properties e.g. density 19.3g/cm3, melting point (liquid) 3422℃,?electricity conductivity 30% IACS min and hardness 69hra min. It owns?special characters including low thermal expansion, good thermal conductivity, sufficient resistance and high elastic modulus. The bar?is widely applied in various fields, e.g. support line, lead-in line, printer needle, various electrodes, quartz furnace, filament, high-speed tools, automatic products, sputtering target and heating devices…

There are many factors, which can influence the welding effort of resistance welding, which is applied tungsten copper as electrodes, such as welding current, time, pressure, electrode shape and properties and workpiece surface condition. 1.0 Influence of welding current The influence of current on heat generation is greater than both resistance and time. Therefore, in the spot welding process, it is a parameter that must be strictly controlled. The main causes of current changes are grid voltage fluctuations and changes…

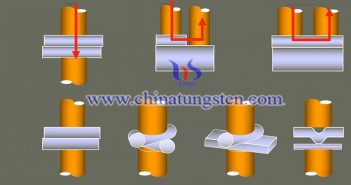

There are four types of resistance welding, which can use tungsten copper bonded copper electrode as welding tip, spot welding, seam welding, butt welding and projection welding. Spot welding assembles the weldment into a lap joint and presses it between two cylindrical electrodes to melt the base metal using resistance heat to form a solder joint, which is mainly used for thin plate welding. The processes are preloading to ensure good contact of the workpiece, energizing to form nugget and…

Tungsten copper is a material with high electricity conductivity, when using for resistance welding, the material is bonded with copper hand. This kind of welding method refers to a method in which electric current passes through the welding objective and the resistance heat generated at the contact point as a heat source to locally heat the objective while pressing for welding. There are many advantages for this kind of welding method, high productivity, low deformation and easy automation realization. The…

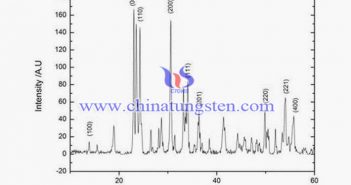

Compared with commercial graphite anode materials for lithium-ion batteries, nano-transition metal oxide anodes have better lithium storage properties and higher theoretical specific capacity, which are more in line with future social development requirements. As far as the transition metal tungsten trioxide is concerned, it is not only eco-friendly, but also low in price and high in theoretical specific capacity. It is undoubtedly a negative electrode material with great development potential. However, bulk tungsten trioxide has low conductivity and large volume…

Network data shows that tungsten trioxide with a particle size in the range of 100nm-1000nm is called submicron yellow tungsten oxide. According to the quantum size effect, although the specific surface area of submicron yellow tungsten oxide is smaller than that of nano tungsten oxide, it still has the advantages of excellent gas sensitivity and not easy to agglomerate. Gas sensitivity can be simply understood as the appearance characteristics of chemical materials, such as color, which easily changes significantly with…

It is reported that the team of Professor Yonghui Deng of Fudan University used the cooperative co-assembly between organic block copolymers and inorganic heteropolyacid molecules to directly synthesize three-dimensional, equally spaced, orthogonally arranged Si-doped ε-WO3 orthogonal nanowire arrays for the first time. And the material has excellent sensor response performance to acetone (acetone is one of the physiological and pathological landmark volatiles in human exhaled breath), which is mainly because the metastable ε-WO3 nanowire array structure has 3D stacking porous…

It is reported that the researchers combined the advantages of graphene’s unique two-dimensional layered structure, excellent electrochemical performance and the wide application characteristics of WO3 nanowires in various dingal fields, and assembled WO3 nanowires as guest materials into the graphene host material. , Control the synthesis conditions to prepare a unique one-dimensional and two-dimensional nanocomposite material, which has great potential application prospects in the fields of chemistry, optics and electricity. The graphene loaded WO3 nanowire composite material is characterized in…