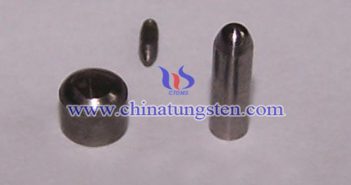

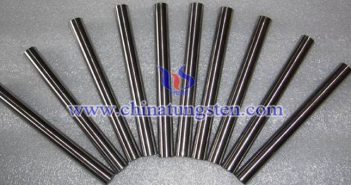

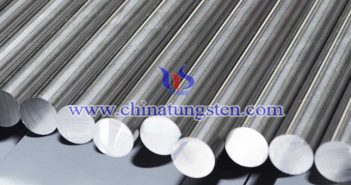

Tungsten nozzle, which can be made of pure tungsten, tungsten alloy or tungsten carbide, is a very important part in many kinds of equipment such as oil injection, sand blasting, and spraying, etc. And therefore, it can be used in many industries such as automobile industry, electroplating industry, and surface treatment industry, etc. Pure tungsten nozzle, tungsten alloy nozzle and tungsten carbide nozzle are different from each other in prosperities, such density, the density of pure tungsten nozzle is about…