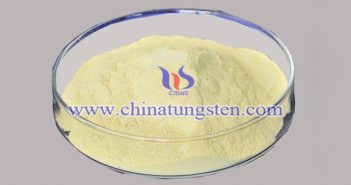

Orthorhombic tungsten trioxide nanoflake may be prepared by hydrothermal method. And the influencing factors on the photocatalytic reaction were studied using photocatalytic degradation of methylene blue by the synthesized WO3 as model. And the photocatalytic properties of orthorhombic WO3 nanoflake were studied by determining the chemical oxygen demand (COD) of methine blue before and after photocatalytic degradation by potassium dichromate method. Hydrothermal Method to Prepare Orthorhombic Tungsten Trioxide Nanoflake The chemical reagents used were of analytical grade and were not…